APPLICATION

Fast connection solutions for liquid cooling systems in various industries

In the context of the universal demand for high efficiency, high productivity and high quality, each industry also requires unique technical solutions. Our technical team tailors the best solutions for different media, different working environments and different operating conditions.

Liquid cooling connectivity solutions for the data center and energy storage industries

With the start of the national “East count west count” project, digitalization has become a new economic engine and development direction of the country. As computing power continues to improve, so does the need for data protection and large storage capacities. The energy exchange involved means liquid cooling is a must.

Drip-free with pressure connection technology

Allows online hot swapping (replacing blades and racks without stopping equipment), making maintenance easier and protecting IT systems. The excellent performance of our quick couplings ensures uninterrupted operation and high reliability of your equipment. Our connectivity solutions span data centers, energy storage, supercomputers and other computer and electronic systems.

l Liquid cooling source and chiller quick connection

High-flow connectors for data center water treatment. The VLA series connector diameters from DN20 to DN50 ensure leak-free connections and optimal flow rates, reducing energy consumption.

l Branch manifold blind plug connection

Blind connectors for branch manifples and blade servers, compact, flat head disconnects without leakage, support pressure connections to keep your system working. The unique floating structure design makes the system work more stable and reduces the system cost.

l Branch manifold is manually connected

CB series steel ball locking joint and CS series buckle locking joint, for manually operated water separator and water cooling plate connection, compact, easy to operate, optional with pressure connection and self-discharging pressure function.

Gas-liquid two-phase quick couplings for fluorides

The VAF series flat head leak-free connectors are specially designed for fluoride gas-liquid two-phase cooling systems. Clean disconnect without any leakage, no need to re-fill the circuit refrigerant. The special structural design allows the VAF series connectors to be hot-swappable with pressure, ensuring uninterrupted operation and high reliability of your system. The threaded connection ensures absolute security of the connection.

l Military air conditioning cooling

l fluoride forced refrigeration

l fluoride data center cooling

Liquid cooling fast connection solution for power electronic equipment

The liquid cooling of power electronics requires absolute tightness, and the flat head leak-free quick couplings are ideal for thermal management circuits and ensure long-term reliability. For different cooling media, we offer stainless steel and surface treated aluminum alloy quick couplings. From wind power photovoltaic inverters, to military pods and electronic enclosures, we have proven solutions and application experience. The special floating design makes our blind connectors more suitable for modular cooling systems in small Spaces. The application of pressure connection technology and self-relieving pressure technology ensures uninterrupted work of your system and maintains long-term reliability.

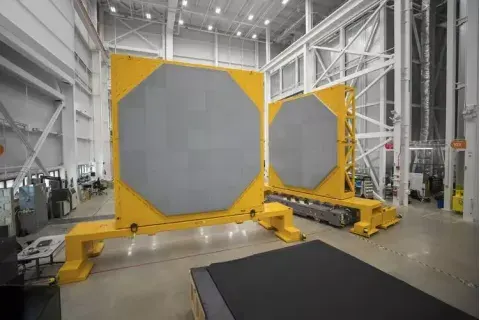

Phased array radar and power amplifier blind plug connection

Phased array radar has compact structure and narrow space, which requires high reliability and compact of fluid connector. Our blind connectors are compact, floating for safer system operation, and are available with pressure connections and self-discharging pressure structures. The CN series allows a maximum of ±0.5mm misaligned connection, and the CNB series allows a maximum of ±1mm misaligned connection. Our design team can also design embedded or other non-standard connections to make your system more compact and reliable over the long term.

l Military power supply and electronic chassis quick connection

For the cooling circuit of the water cooling plate, water distributor and liquid cooling source, the CS buckle is perfect for quick on-off without leakage. Stainless steel and surface treated stainless steel joints are available for different corrosion protection requirements. The buckle connection makes the CS series more suitable for use in vibration environments. For the water-cooled plate connection that needs to be inserted and removed frequently and transferred, we recommend the use of a socket with self-discharging pressure, the water-cooled plate pressure automatic unloading, preventing the water-cooled plate drum bag, so that the transfer is safer.

For multiple power modules in the chassis, the blind plug connection is the industry’s preferred, specially designed floating structure to make your system more secure and reliable.

l Wind power photovoltaic inverter manual connection

Wind power photovoltaic and rail transit industry a large number of applications of inverters, as the power continues to increase, liquid cooling has become the standard. CB Series steel ball locking connectors are particularly suitable for fast connection of inverter cooling circuits. The structure is simple and reliable, and the material is aluminum alloy and stainless steel. Optional pressure connections and self-discharging pressure structures allow the system to work continuously and have long-term reliability. Thanks to the large number of uses in the civil industry, the CB series has a better price and cost performance, suitable for applications where the environment is relatively stable and controllable.

Marine and Marine liquid cooled quick couplings

The ship and Marine industry has high requirements for anti-corrosion, and the cooling medium is diverse and uncontrollable. The flat head non-leakage quick joint of Wanshuo can be selected 304 or 316L stainless steel, and the sealing ring is more environmentally adaptable HNBR. Our stainless steel 316L blind joint has been used on military ships for a long time without leakage, even in shipboard environments where sea water is the cooling medium.

In ship-to-electric energy storage equipment cooling, port heavy AGV transfer vehicles and electric drive tower cranes and other applications, Wanshuo’s leak-free quick connectors also perform well. We can provide a full range of stainless steel quick couplings, and can be customized according to customer requirements.

Laser cooling fast connection solution

High power lasers require absolute sealing of the quick joint, and some lasers are even immersed directly in the coolant. The surface treated aluminum alloy non-leakage quick joint fully meets the requirements of laser cooling, has no corrosion after long-term use, and does not affect the performance of the laser. Some ultra-high power lasers use gas-liquid two-phase cooling system, and the specially designed buckle joint and blind insert joint can fully adapt to the gas-liquid two-phase environment. Masson’s leak-free quick connector performs well in airborne laser cooling and receives a list order.

New energy vehicles and charging pile liquid cooling quick connection solution

Domestic sales of new energy vehicles will exceed 5 million in 2022, and sales are expected to exceed 10 million in 2025. The demand for liquid cooling in the booming new energy automobile industry will also continue to increase. The floating blind connector makes quick power changes possible. The application of non-leakage quick connector makes high current fast charging of charging pile possible. In the field of hydrogen powered vehicles, the cooling of hydrogen batteries and rapid hydrogenation have become the future research direction of Wanshuo.

The power battery and preheating module are connected in blind slot

The new energy vehicle power battery generally adopts liquid cooling, and the floating blind plug connector makes it possible to quickly change the power. In mainstream electric vehicles such as Tesla and NIO, blind plug connections have become standard. The blind series of quick couplings allows for a maximum of ±1mm misalignment, making power changes more efficient and reliable. At the same time, we can also carry out non-standard design, so that the cooling circuit and the electrical circuit are disconnected at the same time, and ensure long-term reliability.

l Manually connect the cooling circuit of the charging pile

High current high power fast charging, there is inevitable power loss, heat loss requires a powerful liquid cooling system to take away the heat. The application of non-leakage quick connector makes the installation and maintenance of the liquid cooling module more simple and efficient. CB series aluminum alloy joint has compact structure, easy operation and good cost performance, especially suitable for batch use of charging piles.

LIQUID COOLING TECHNOLOGY

Liquid cooling technology is a heat dissipation technology that uses the flow of liquid to quickly take away heat. Liquid cooling application refers to the use of liquid cooling plate (also called water cooling plate, liquid cooling radiator) installed at the heat source, with heat exchangers and heat pumps, to dissipate heat in the form of liquid circulation flow. In general, liquid cooling technology is used in environments where forced convection or phase change systems cannot achieve high thermal energy density.

The research and development of liquid cooling technology continues to increase, especially in the production process of water-cooled products continuous innovation, in the automatic bending of copper pipe, extrusion mold, pressure pipe, adhesion welding and other technical processes have obtained a number of technical patents, making the water-cooled plate welding more stable, greatly reducing the water plate leakage and other adverse phenomena, improve the reliability of water-cooled plate heat dissipation; Through the technical treatment of the surface of the liquid cooling plate, the contact with the heat source is better and the heat dissipation efficiency is improved.

Liquid cooling technology options available: Buried pipe forming water cooled runner + pipe joint:

- Extrusion molding water cooled runner + welding

- Machined water-cooled runner + welding

- Die casting water cooled runner + welding

Water-cooled cooling solutions provide joint options:

Water cooling solutions provide pipe options:

corrugated pipe

straight pipe